Independently Verified Precision

Introduction

Each of Avidien’s instruments are validated by a third party calibration laboratory. These calibration results are obtained gravimetrically using Grade 3 purified water, equipment manufacturer or validated substitute tips, and ISO8655 compliant test equipment traceable to NIST and through NIST to the International System of Units (SI). Additionally, each microPro instrument must pass Avidien’s strict quality control standards. The head assembly characterization process analyzes the absolute position of the drive system throughout the entire working volume. This ensures the instrument dispenses from every channel very precisely. These processes are time-consuming and expensive for 96-well pipettors such as the microPro 300, but necessary in order to maintain confidence in the data generated from any liquid handling device.

An alternative method for validation of the accuracy and precision of 96-channel pipettes is photometry. Avidien employed Artel to test three randomly selected microPro 300 instruments with its Multichannel Verification System (MVS) in order to verify that they meet or exceed the performance specifications presented to our customers. This technical report will describe these tests and provide their results along with some discussion.

Product Description

The microPro 300 is a 96 well semi-automated benchtop pipettor with a working volume of 5 to 300μL. With 5 preset pipetting modes and options for creating a custom mode specific to your application.

Materials and Methods

Artel’s proprietary dual-dye ratiometric photometry method is a recognized method for micropipette calibrations as described in ISO 8655-7, and for automated liquid handlers as described in the ISO IWA 15 agreement. The MVS uses this method to provide accuracy and precision data for each channel in a multichannel liquid delivery device.

This system uses custom manufactured microtiter plates, characterized sample solutions, stock solutions, diluent, and baseline solution, a specialized calibrator plate, a customized microtiter plate reader, and its own MVS software to manage the data, which results in a measurement system with traceability to the International System of Units through national standards.

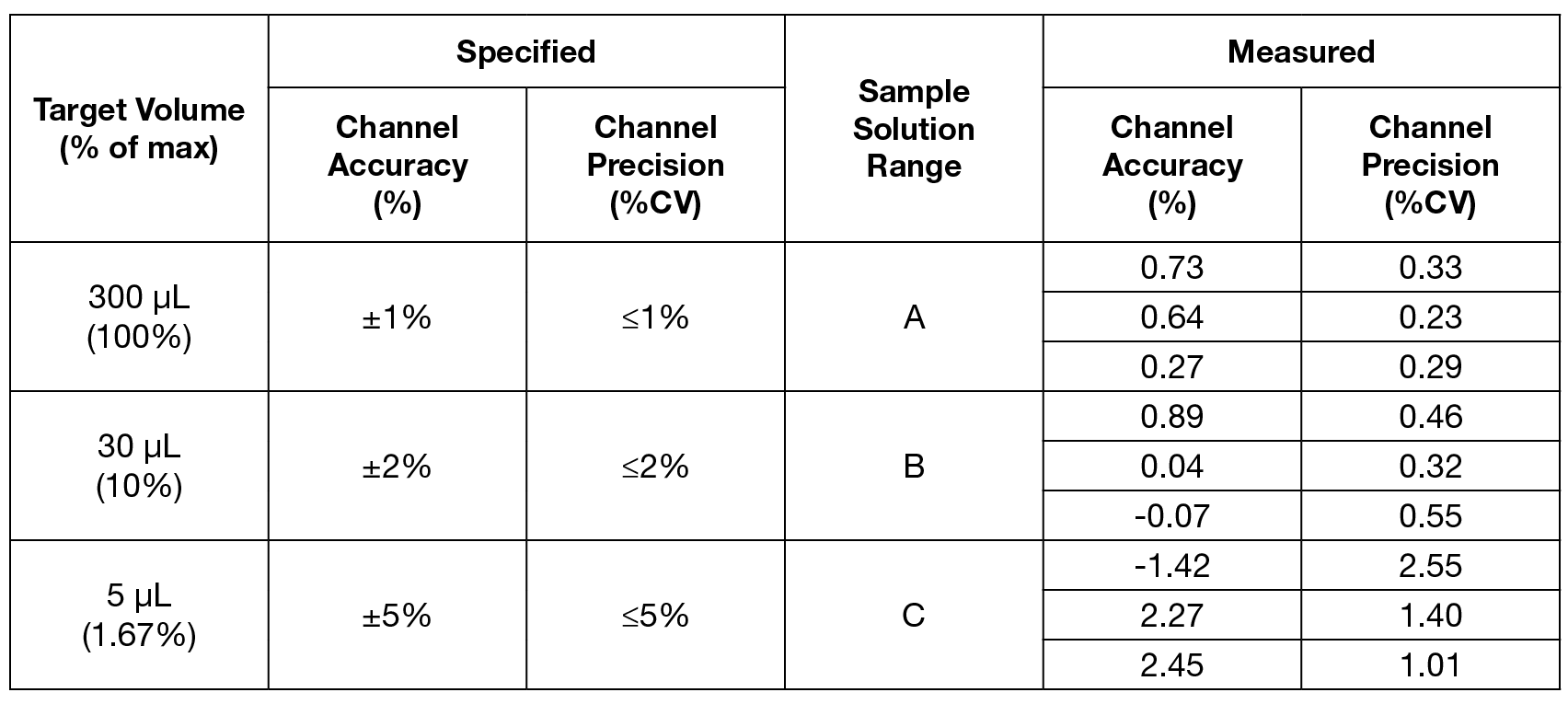

Each of the instruments were tested at target volumes of 1.67%, 10%, and 100% of the maximum volume in their working volume range. Each instrument dispensed each target volume five times and a summary of accuracy and precision data can be found in the results section of this report.

Technical Data Pipetting System

Table 1: Technical Data for microPro 300.

Results

Precision of microPro 300 verification

Table 2: Performance specifications and results of MVS measurement of Avidien microPro 300 instruments.

Discussion

The verification data reported by the Artel MVS displays the microPro 300’s ability to perform extraordinarily well throughout its stated volume range, exceeding performance specifications at 5, 30, and 300μL in real world tests.

Repeatable Results Every Time

Want to learn more about how the Avidien microPro 300 can help drive consistency and repeatability in your experiments? Check out our blog posts on Optimizing Your 96 Channel Pipettor for Maximum Liquid Recovery and Eliminating Common Pipetting Errors for Repeatable Results, or contact us now.